General framework of the activity

Process modelling

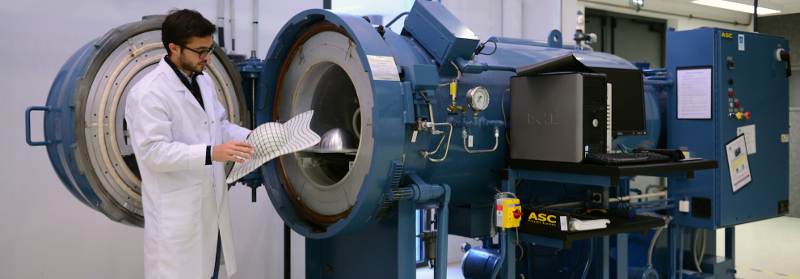

The objectives of the PMM team in all the processes studied is to reduce costs (non-autoclave processes), to allow for an optimized design (robotic placement, welding) and to produce at high speed (stamping of thermoplastic prepregs and semi-pregs, high pressure RTM injection).

Several scales can be modeled (at the micro scale of the fiber, at the meso scale of the centimeter, and at the macro scale of the meter) and different physical simultaneously (mechanical, thermal, fluidic, and chemistry).

Robust models of manufacturing processes – the object of increasing interest from industry and researchers

Manufacturers need to have digital and analytical tools capable of predicting the performance of manufacturing processes in order to simultaneously design the product and its process of industrialization under the more general concept of “Virtual Manufacturing”. It is therefore a question of putting in place methods and tools, incorporating business constraints and which are based on a scientifically formalized approach to develop, analyze and optimize efficient manufacturing processes, both for the process (sequencing of tasks) and for the method, by integrating their interactions with the product.

Specific skills in the MRE field

Composites materials and processes for tidal or wind turbine blades:

The laboratory has three complementary skills to optimize the manufacturing processes of composites:

- Analysis and detailed physical understanding of the phenomena involved during the composite manufacturing stage

- On this basis, development of multiphysical numerical models (chemistry / thermal / flow) describing the dynamics of fiber impregnation with resin, polymerization, fiber reorganization.

- For a given configuration, specific experiments make it possible to better understand the physics of impregnation and to quantify the input data of the models: visualization of the flow under a tomograph, etc. Quantities such as the tensor of permeability of the tissue fibers, or the coefficient of friction between two tissue frames, are determined by specific experiments developed by the laboratory.

These three complementary skills make it possible to define the parameters influencing the quality of manufacture and the search for the best compromise between, for example, fatigue behaviour (which requires a high fibre content) and ease of implementation (which requires looser fabrics). , as well as the development of manufacturing ranges to limit the appearance of defects such as resin pockets, crack initiation zone that reduce the mechanical properties.

The resulting optimizations of manufacturing ranges can be evaluated on other equipment of the laboratory at scales of the order of m².

Among the case studies considered, large-scale studies (blade> 80m) are treated with a stochastic model reduction technique, with a solution taking into account the multi-physical origin (chemistry / thermal / flow) of the phenomena.

Test facilities applicable to MRE

Projects in MRE

PhD thesis, int the PMM Team of Kourkoutsaki, Theodosia : A Multiphysics Simulation Toolkit Developed to Address Scale-up Challenges of Out-of-Autoclave Composites Manufacturing