Key characteristics

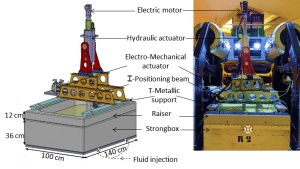

The Université Gustave Eiffel Pile driver for centrifuge models gives the opportunity to study the installation and loading model piles without stopping the centrifuge :

- Installation of model pile in the centrifuge by pile driving in flight at 100×g

- Energy delivered to the pile : 3MJ (at 100×g)

The pile driver, developed with the support of the WEAMEC REDENV-EOL project (2017-2021) and the ANR FEM SOLCYP+ project (2017-2020).

THE PILE DRIVER IN VIDEO

Operation of the pile drive at 1xg

Operation of the pile driver accelerated 60 times : pile driving of a monopile in a scale model, then, without stopping the centrifuge, the lateral loading

Equipment

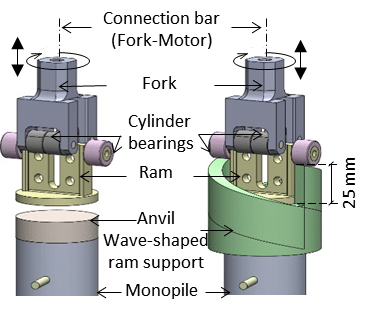

- Hammer (maximum stroke 25mm)

- Hydraulic jack with hollow rod (adapting the altitude of the device to the pile settlement)

- Connection bar (Fork-Motor)

- Electric motor (rotation of the ram: max 1000 rpm)

Services

- Installation of instrumented model monopile at 100×g

- Embedment generated equivalent to 25m (for Ø=5m)

- Number of strokes per second at model scale : 30 (corresponding to 900 rpm)

Example of MRE applications

- Pile driving followed by lateral cyclic loading

This equipment is used in the WEAMEC project REDENV EOL and in Semaan Maatouk’s thesis (2019-2022), co-funded by the Gustave Eiffel University and the Pays de la Loire Region, and entitled “Centrifuge modeling of the installation mode of offshore wind turbine monopiles”.